Case making

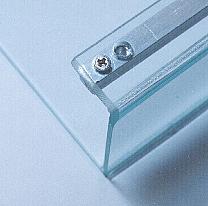

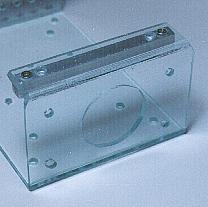

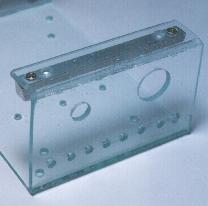

for the infrared sensor

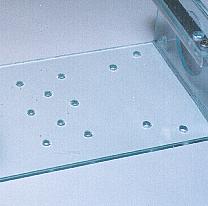

I introduce the way of making the case which used the acrylic board in this page. I used "Bending apparatus-2" to bend the acrylic board. The acrylic board which was used this time had the trace like the bubble when it applied heat. The advantage in the corner is bad a little.   The bottom The bottom I made the front panel, the back panel and a cover installation part, using Bending apparatus-2. The after work is easy when bending a cover installation part first.  The cover fixation metal fittings The cover fixation metal fittings I made cover installation metal fittings using the aluminum square lumber of 6 mm. The metal fittings are fixed on the cover installation part with the plate screw of 2 mm. I used the 3 mm screws for the fixation of the cover.  The cover The cover I made a cover after making the bottom. The cover is bent according to the size of the bottom. To make length on either side the same, I was cut after the bend of the cover was ended.  The fixation of the lens The fixation of the lens The Fresnel lens which I used is doing a cylinder and there are not holes for the fixation. Therefore, I decided to put in with the acrylic board from the back to fix a lens. I used the several plain washers for adjusting the interval of the acrylic board for the lens fixation and the front panel.  The front panel The front panel A Fresnel lens is installed on the front panel. I opened a hole with 27-mm diameter, using the reamer to install a lens. I used a reamer with 30-mm diameter. When making a hole with the reamer, it is necessary to open out carefully because it doesn't sometimes become a beautiful circle when the hole becomes big.  The back panel The back panel I put a variable resistor for the light adjustment, an output terminal and a power supply connector to the back panel. I made the holes according to the size of each part. I put a back panel sheet together when installing the parts.  The bottom The bottom The infrared detection unit is put to the bottom. The holes are opened according to the position of the stud. At the equipment this time, the parts which generates a lot of heat aren't used. However, I made small holes for the radiation for the safety. I made the similar holes in the cover, too. |